Your Trusted Service Provider !

Showroom

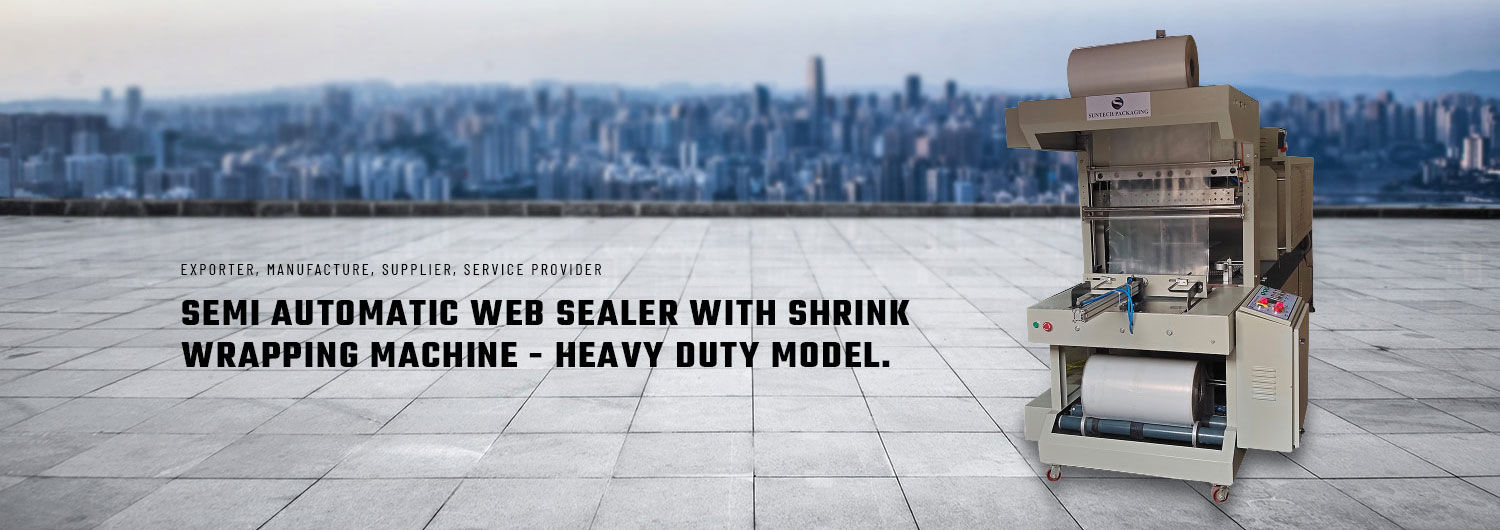

Wrapping machines, typically constructed with durable MS material, automate packaging processes. They boast an automatic grade, driven by an electric motor, and feature a user-friendly Human Machine Interface for control. With warranties included, they come in various designs and types, catering to diverse industries for efficient packaging operations.

Shrink tunnel machines, often built from durable metal, like the Bottle Shrink Tunnel Machine, operate automatically, supporting 220V or 440V. Managed through Human Machine Interface, they efficiently shrink-wrap products, optimizing packaging. Their advanced technology ensures precise temperature control and shrinkage, serving various industries for enhanced product presentation and protection.

Strapping machines, made of durable metal, come in automatic and semi-automatic grades with warranties. They feature user-friendly interfaces, efficiently securing packages. Versatile in size and type, they employ precise strapping techniques, reducing manual labor and enhancing efficiency in logistics and manufacturing. Their robust structure makes them indispensable in modern packaging.

Liquid filling machines, often made from resilient metal or stainless steel, use electric drives and come with warranties. Managed through Human Machine Interfaces, they offer high efficiency and automatic functionality, compatible with voltages from 220 to 440 volts. Essential in various industries, they optimize liquid packaging processes with adaptable dimensions and broad applications.

Sealing machines, operating at 220V to 440V, cater to industrial needs with semi-automatic or automatic grades. Their sturdy design withstands industrial environments, sealing materials with precision using heat, pressure, or adhesive methods. Widely used in food, pharmaceuticals, and manufacturing, they ensure packaging efficiency and product integrity with reliable performance.

In industry, a shrinking machine operates at 220 volts, with automatic features, managed through a Human Machine Interface, ensuring precision. Its robust structure and sleek design facilitate effortless operation. Employing cutting-edge technology, it precisely shrinks packaging materials, meeting manufacturing, logistics, and retail needs, catering to diverse packaging requirements with intuitive interfaces.